| Availability: | |

|---|---|

| Quantity: | |

SO Flange

SDFL

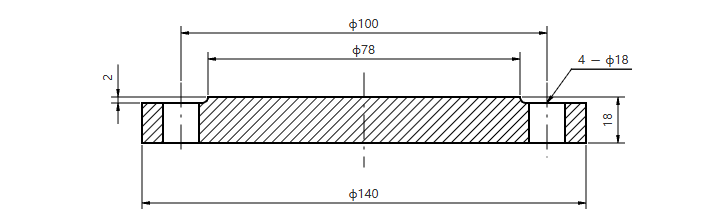

This EN 1092-1 05B DN32 PN25 blind flange is purpose-engineered for pipeline pressure testing and temporary isolation scenarios. Its rugged blank face design (Type 05B) and PN25 (2.5 MPa) rating ensure reliable sealing during hydrostatic, pneumatic, or vacuum tests. Constructed from S235JR carbon steel (1.0037)—a cost-effective material with 235 MPa minimum yield strength—it balances performance and affordability for industrial testing applications.

Parameter | Details |

Standard | EN 1092-1 Type 05B (Blind Flange) |

Material | Carbon steel S235JR (1.0037) |

Pressure Rating | PN25 (2.5 MPa) |

Dimensions | OD: 140mm, Bolt Circle: 100mm, Thickness: 18mm |

Bolt Holes | 4x M16 (pitch circle diameter 100mm) |

Seal Type | Flat Face (FF) |

Temperature Range | -20°C to 300°C |

Testing Compliance: Validated through hydrostatic testing at 3.75 MPa (1.5x rated pressure) to meet ISO 15649-1 standards for pipeline integrity verification.

Corrosion Protection Options: Optional hot-dip galvanizing (HDG) per ISO 1461 adds a 85μm+ zinc coating, extending lifespan by 5+ years in outdoor or buried applications.

Universal Compatibility: Bolt holes precisely aligned to EN 1092-1 PN25 standards ensure quick integration with existing flanged systems without modification.

Structural Integrity: CE-marked per PED 2014/68/EU and compliant with EN 1090-2 for structural steelwork, guaranteeing performance in safety-critical testing.

Oil & Gas: Seals pipeline sections during 1,500+ psi hydrostatic tests, ensuring compliance with API 1104 welding standards for transmission lines.

Water Treatment: Isolates filtration systems during chlorine disinfection processes, with HDG coating resisting pH 3–11 environments in municipal water networks.

Construction: Used in high-rise building plumbing for pressurized water supply testing, with S235JR’s ductility absorbing thermal expansion stresses.

Q: Can this flange be reused after testing?

A: Yes, if inspected for gasket seating surface damage and re-torqued to 120–150 N·m for M16 bolts before reinstallation.

Q: What gasket works best for steam testing?

A: Graphite-reinforced PTFE gaskets (EN 1514-2) rated for 300°C+ provide reliable sealing in saturated steam applications up to 18 bar.

Q: How to correct flange misalignment during installation?

A: Use EN 1092-1 Annex B alignment pins to adjust for up to ±1.0mm positional misalignment, ensuring proper gasket compression.

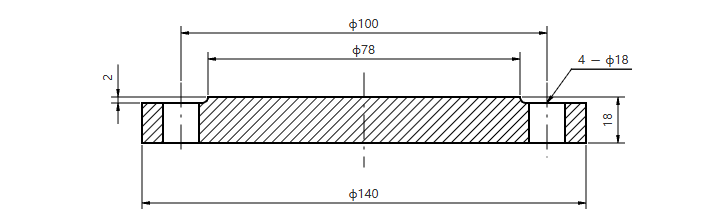

This EN 1092-1 05B DN32 PN25 blind flange is purpose-engineered for pipeline pressure testing and temporary isolation scenarios. Its rugged blank face design (Type 05B) and PN25 (2.5 MPa) rating ensure reliable sealing during hydrostatic, pneumatic, or vacuum tests. Constructed from S235JR carbon steel (1.0037)—a cost-effective material with 235 MPa minimum yield strength—it balances performance and affordability for industrial testing applications.

Parameter | Details |

Standard | EN 1092-1 Type 05B (Blind Flange) |

Material | Carbon steel S235JR (1.0037) |

Pressure Rating | PN25 (2.5 MPa) |

Dimensions | OD: 140mm, Bolt Circle: 100mm, Thickness: 18mm |

Bolt Holes | 4x M16 (pitch circle diameter 100mm) |

Seal Type | Flat Face (FF) |

Temperature Range | -20°C to 300°C |

Testing Compliance: Validated through hydrostatic testing at 3.75 MPa (1.5x rated pressure) to meet ISO 15649-1 standards for pipeline integrity verification.

Corrosion Protection Options: Optional hot-dip galvanizing (HDG) per ISO 1461 adds a 85μm+ zinc coating, extending lifespan by 5+ years in outdoor or buried applications.

Universal Compatibility: Bolt holes precisely aligned to EN 1092-1 PN25 standards ensure quick integration with existing flanged systems without modification.

Structural Integrity: CE-marked per PED 2014/68/EU and compliant with EN 1090-2 for structural steelwork, guaranteeing performance in safety-critical testing.

Oil & Gas: Seals pipeline sections during 1,500+ psi hydrostatic tests, ensuring compliance with API 1104 welding standards for transmission lines.

Water Treatment: Isolates filtration systems during chlorine disinfection processes, with HDG coating resisting pH 3–11 environments in municipal water networks.

Construction: Used in high-rise building plumbing for pressurized water supply testing, with S235JR’s ductility absorbing thermal expansion stresses.

Q: Can this flange be reused after testing?

A: Yes, if inspected for gasket seating surface damage and re-torqued to 120–150 N·m for M16 bolts before reinstallation.

Q: What gasket works best for steam testing?

A: Graphite-reinforced PTFE gaskets (EN 1514-2) rated for 300°C+ provide reliable sealing in saturated steam applications up to 18 bar.

Q: How to correct flange misalignment during installation?

A: Use EN 1092-1 Annex B alignment pins to adjust for up to ±1.0mm positional misalignment, ensuring proper gasket compression.