| Availability: | |

|---|---|

| Quantity: | |

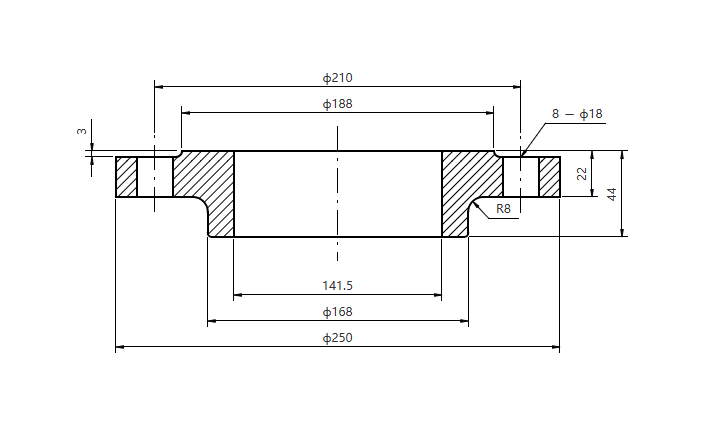

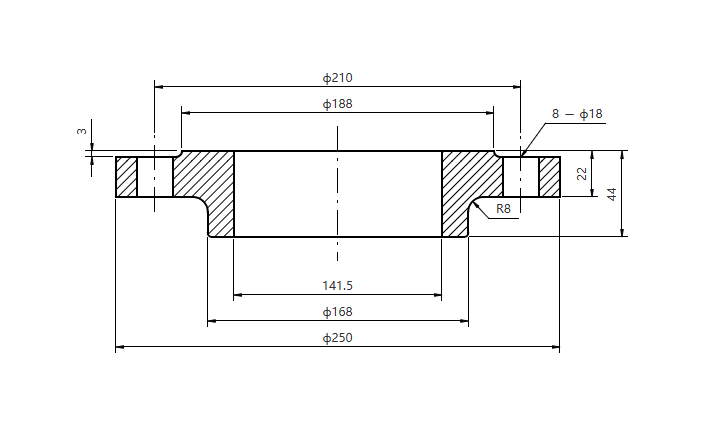

SO Flange

SDFL

In accordance with EN 1092-1 and relevant standards (such as EN 10204), the manufacturing and inspection of flanges must meet the following requirements:

• Manufacturing processes: Usually forging (die forging or open die forging) or casting (which needs to meet more stringent quality requirements). Cutting medium and heavy plates can also be used to make flanges, but there are limitations.

• Dimensional tolerances: All dimensions must be within the tolerances specified in the standards (such as outer diameter D, bolt hole circle K, sealing surface dimensions, etc.).

• Surface treatment: The sealing surface must achieve the specified surface finish (roughness Ra value) to ensure that the gasket can effectively seal.

• Non-destructive testing: Depending on material specifications and order requirements, ultrasonic testing (UT), magnetic particle testing (MT) or penetrant testing (PT) may be required to check for internal and surface defects.

• Material certificates: It is usually required to provide material inspection certificates conforming to EN 10204-3.1 or 3.2 type, proving that their chemical composition and mechanical properties (such as tensile strength, yield strength, impact toughness) meet the standard requirements.

• Pressure testing: Flanges themselves as individual components are generally not subject to separate pressure testing, but the piping systems composed of them must undergo pressure testing.

In accordance with EN 1092-1 and relevant standards (such as EN 10204), the manufacturing and inspection of flanges must meet the following requirements:

• Manufacturing processes: Usually forging (die forging or open die forging) or casting (which needs to meet more stringent quality requirements). Cutting medium and heavy plates can also be used to make flanges, but there are limitations.

• Dimensional tolerances: All dimensions must be within the tolerances specified in the standards (such as outer diameter D, bolt hole circle K, sealing surface dimensions, etc.).

• Surface treatment: The sealing surface must achieve the specified surface finish (roughness Ra value) to ensure that the gasket can effectively seal.

• Non-destructive testing: Depending on material specifications and order requirements, ultrasonic testing (UT), magnetic particle testing (MT) or penetrant testing (PT) may be required to check for internal and surface defects.

• Material certificates: It is usually required to provide material inspection certificates conforming to EN 10204-3.1 or 3.2 type, proving that their chemical composition and mechanical properties (such as tensile strength, yield strength, impact toughness) meet the standard requirements.

• Pressure testing: Flanges themselves as individual components are generally not subject to separate pressure testing, but the piping systems composed of them must undergo pressure testing.