Material and Process Requirements

(1) Material Selection Guide Material Grade Applicable Medium Temperature Range Surface Treatment

P265GH (Carbon Steel) Water, Steam, Oil Products (Non-corrosive) -20°C to 350°C Hot-dip Galvanizing (≥80μm)

1.4404 (316L) Acidic Medium, Seawater -196°C to 600°C Electropolishing (Ra≤0.8μm)

1.4462 (Duplex Steel) Chloride-ion-containing Environment -50°C to 300°C Pickling and Passivation

(2) Manufacturing Process Control Forging Process:

Forging Ratio ≥ 4:1 (Required by EN 10222-3)

Grain Size ≥ ASTM Grade 5 (Metallographic Inspection)

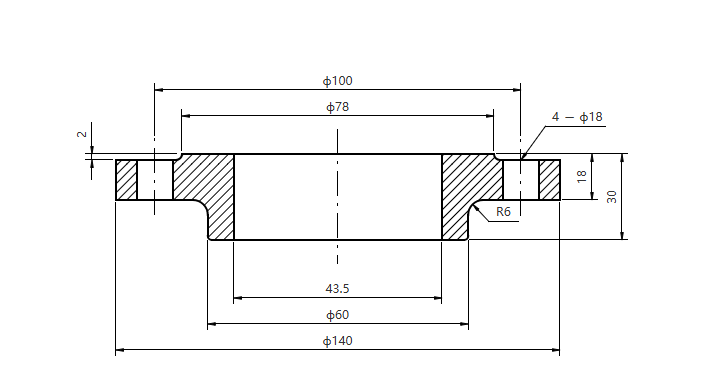

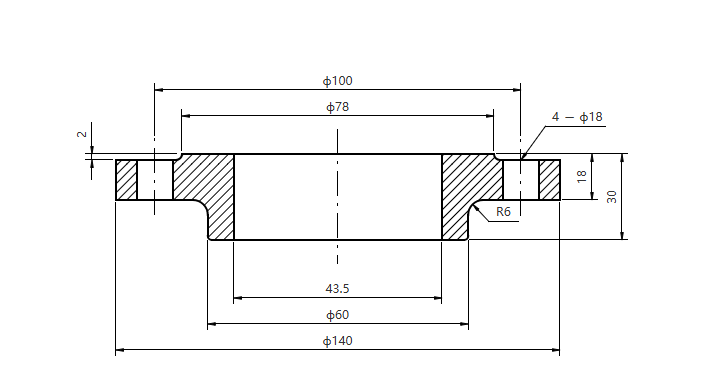

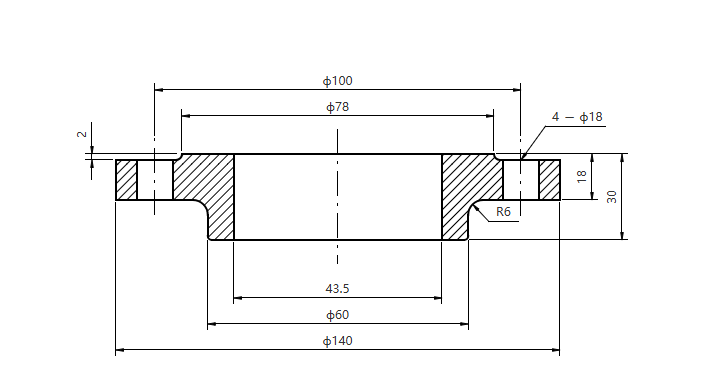

Machining Requirements:

Runout of Sealing Surface ≤ 0.05mm (Measured by Dial Indicator)

Position Tolerance of Bolt Hole ≤ φ0.3mm (Measured by CMM)