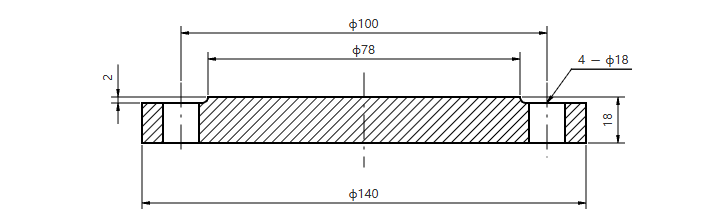

An Essential, High-Efficiency Tool for Maintenance & Testing

In plant operations and upkeep, BS EN 1092-1 blank flanges play a

vital role. Installing a blank flange is the safest and most thorough method to isolate specific pipeline sections during equipment repair, valve replacement, or line modification, protecting personnel and preventing cross-contamination. Crucially, they are

key components for pressure testing (hydrostatic/pneumatic), sealing open ends to create a closed test environment. Their standardized design facilitates quick installation and removal,

significantly enhancing maintenance efficiency and testing reliability.