| Availability: | |

|---|---|

| Quantity: | |

SO Flange

SDFL

The EN 1092-1 DN32 PN10 F316 slip-on flange is purpose-built to excel in corrosive environments where standard stainless steel flanges may fail. Its larger DN32 (1-1/4") size and premium F316 material—enhanced with molybdenum—deliver superior resistance to chemical attack, making it ideal for handling aggressive media such as seawater, industrial wastewater, and acidic solutions. Designed for low-pressure (1.0 MPa) yet high-reliability applications, this flange combines ease of installation with long-term durability in European and global industrial systems.

Parameter | Details |

Standard | EN 1092-1 Type 11 (Slip-On flange) with full CE certification |

Material | Stainless steel 1.4401 (F316) containing 16-18% chromium, 10-14% nickel, and 2-3% molybdenum |

Seal Type | Raised Face (RF) with 1.6mm sealing projection, compatible with EN 1514-2 spiral-wound gaskets |

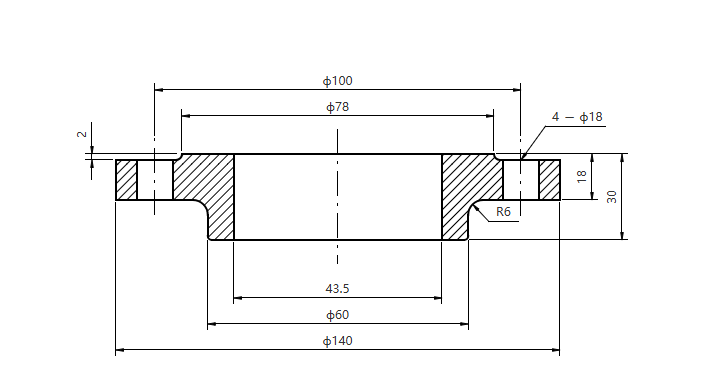

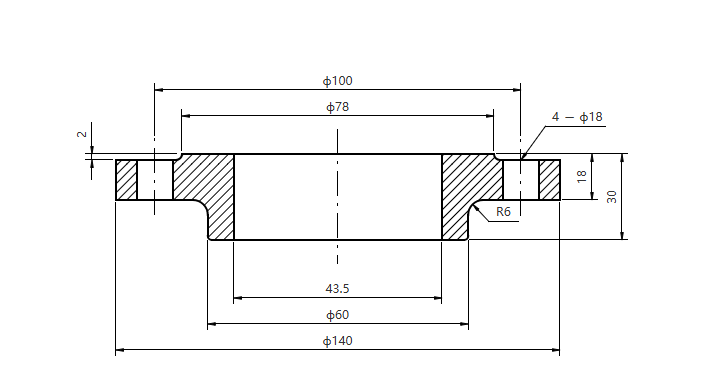

Dimensions | OD: 140mm, Bolt Circle: 100mm, Thickness: 16mm, 4x M12 bolt holes (pitch circle diameter 100mm) |

Superior Corrosion Resistance: F316’s molybdenum content creates a dense oxide layer that resists chloride pitting (critical in seawater with 19,000–35,000 ppm chloride levels) and sulfuric acid corrosion, outperforming F304 by 2–3x in aggressive settings.

Slip-On Convenience: Designed to fit DN32 pipes (outer diameter 38.0mm) with minimal clearance, requiring only two fillet welds (inner and outer) for secure attachment—reducing welding time and material costs compared to heavy-duty flanges.

High-Durability: PN10 rating ensures consistent performance in low-pressure/high-flow systems (up to 1.0 MPa), with a design life exceeding 15 years in properly maintained industrial environments.

European Certification: Compliant with EN 1092-1 dimensional standards and PED 2014/68/EU pressure equipment regulations, meeting safety requirements for use in machinery, process plants, and water treatment facilities.

Marine Engineering: DN32 flanges connect shipboard saltwater cooling systems, where their chloride resistance prevents pitting in pipelines carrying seawater for engine cooling.

Pharmaceuticals: F316’s biocompatibility (meeting USP Class VI standards) and smooth surface finish make it suitable for sterile process lines in drug manufacturing, resisting cleaning agents like sodium hydroxide.

Mining: Handles abrasive slurries in mineral processing plants, with corrosion resistance to mineral acids (e.g., sulfuric acid used in leaching processes) and wear resistance from precision machining.

Q: Is F316 suitable for high-temperature use?

A: Yes. F316 maintains tensile strength above 500 MPa at temperatures up to 600°C, making it ideal for steam tracing lines in chemical processing and food sterilization systems.

Q: Can this flange be used with ASME pipes?

A: Yes, with adapter kits. Use EN-to-ASME reducer flanges (e.g., DN32 to NPS 1-1/4") to bridge metric and imperial systems, ensuring proper alignment and pressure compatibility.

Q: What gasket materials are recommended?

A: For corrosive media, use EPDM or PTFE gaskets (rated for -20°C to 150°C); for high-temperature applications, select graphite-based gaskets with 316 metal reinforcement.

The EN 1092-1 DN32 PN10 F316 slip-on flange is purpose-built to excel in corrosive environments where standard stainless steel flanges may fail. Its larger DN32 (1-1/4") size and premium F316 material—enhanced with molybdenum—deliver superior resistance to chemical attack, making it ideal for handling aggressive media such as seawater, industrial wastewater, and acidic solutions. Designed for low-pressure (1.0 MPa) yet high-reliability applications, this flange combines ease of installation with long-term durability in European and global industrial systems.

Parameter | Details |

Standard | EN 1092-1 Type 11 (Slip-On flange) with full CE certification |

Material | Stainless steel 1.4401 (F316) containing 16-18% chromium, 10-14% nickel, and 2-3% molybdenum |

Seal Type | Raised Face (RF) with 1.6mm sealing projection, compatible with EN 1514-2 spiral-wound gaskets |

Dimensions | OD: 140mm, Bolt Circle: 100mm, Thickness: 16mm, 4x M12 bolt holes (pitch circle diameter 100mm) |

Superior Corrosion Resistance: F316’s molybdenum content creates a dense oxide layer that resists chloride pitting (critical in seawater with 19,000–35,000 ppm chloride levels) and sulfuric acid corrosion, outperforming F304 by 2–3x in aggressive settings.

Slip-On Convenience: Designed to fit DN32 pipes (outer diameter 38.0mm) with minimal clearance, requiring only two fillet welds (inner and outer) for secure attachment—reducing welding time and material costs compared to heavy-duty flanges.

High-Durability: PN10 rating ensures consistent performance in low-pressure/high-flow systems (up to 1.0 MPa), with a design life exceeding 15 years in properly maintained industrial environments.

European Certification: Compliant with EN 1092-1 dimensional standards and PED 2014/68/EU pressure equipment regulations, meeting safety requirements for use in machinery, process plants, and water treatment facilities.

Marine Engineering: DN32 flanges connect shipboard saltwater cooling systems, where their chloride resistance prevents pitting in pipelines carrying seawater for engine cooling.

Pharmaceuticals: F316’s biocompatibility (meeting USP Class VI standards) and smooth surface finish make it suitable for sterile process lines in drug manufacturing, resisting cleaning agents like sodium hydroxide.

Mining: Handles abrasive slurries in mineral processing plants, with corrosion resistance to mineral acids (e.g., sulfuric acid used in leaching processes) and wear resistance from precision machining.

Q: Is F316 suitable for high-temperature use?

A: Yes. F316 maintains tensile strength above 500 MPa at temperatures up to 600°C, making it ideal for steam tracing lines in chemical processing and food sterilization systems.

Q: Can this flange be used with ASME pipes?

A: Yes, with adapter kits. Use EN-to-ASME reducer flanges (e.g., DN32 to NPS 1-1/4") to bridge metric and imperial systems, ensuring proper alignment and pressure compatibility.

Q: What gasket materials are recommended?

A: For corrosive media, use EPDM or PTFE gaskets (rated for -20°C to 150°C); for high-temperature applications, select graphite-based gaskets with 316 metal reinforcement.